Today’s challenging projects demand flawless execution. Our in-house team of expert engineers, planners, technicians, and backup office staff work together to provide

solutions.

We combine creativity with innovation, and modern technology with the expertise of skilled professionals to achieve excellence.

A thorough roadmap is designed before any actual movements are carried out. Total Movements supports customers from

the earliest planning stages by giving detailed advice and pointing out potential logistics issues based on experience and

expertise.

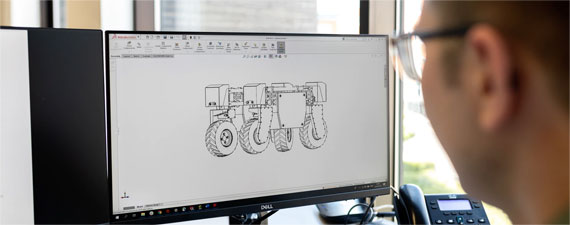

With a team of profoundly qualified engineers, we weave thoughtful solutions for our customers according to their prerequisites. Our Computer-Aided Design (CAD) operators and illustrators create 2D/3D representations of a heavy lift cargo. This assists with heavy transport and lifting simulations, to curate real-time experiences for the internal teams and clients.

The ideal way to stabilize and secure cargo in vehicles and intermodal containers is lashing. The lashing calculations made by our in-house Engineering team ensures the utmost safety of the cargo. It’s important to pick the right lashing equipment and dunnage; use them correctly in order to increase friction, support the piece of cargo and prevent it from moving. The lashing arrangements include:

The progress in manufacturing and the mission to achieve economies of scale are the primary reasons as to why the dimensions/weight of the cargo is increasing by the day. It is important to carry out Route Surveys to ensure smooth movement of ODC (Over Dimensional Cargo), OWC (Overweight Cargo), OOG (Out of Gauge). Our team of expert personnel conducts detailed route surveys and feasibility studies with respect to odd-shaped/weighing cargo as well as permissions and plausibility. Route analysis includes:

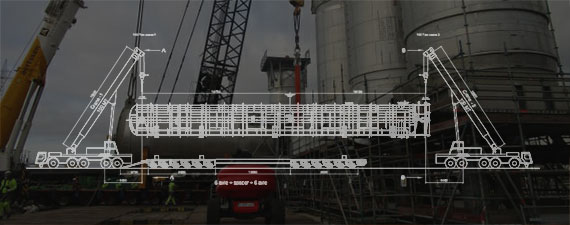

Any complex transportation of ODC/OWC/Project cargo is preceded by meticulous planning and multiple checks. Our team creates a detailed method statement that simulates the different stages of transportation, and the various relevant vehicle/shipping configurations. This is done so that everyone is in the know of the transport planned to be carried out. Our method statement covers a lot of things but a few important ones are mentioned below:

Our team of engineers studies the cargo & lifting requirements in great detail to draw up the lifting plans. A crane lifting plan is provided to the clients for review and approval, prior to performing any lifting operations. The lifting plan includes:

Confined spaces can make it trickier to load, deliver, move, or position heavy cargoes. In order to ensure that there is no damage or interference at these congested spaces with the cargo movement during jacking/skidding, our team of engineers simulates a step-by-step movement of the load vis-a-vis the physical location on AutoCAD. Any obstructions/interferences are highlighted at the beginning of such operations and we work with the clients to avoid/remove them.

Barge Transportations are carried out in a big way for ODC/OWC transportation considering the availability of suitable ships, ports, landing points, etc. Our team of engineers prepares a detailed sea-study analysis as and when required, prior to carrying out such barge transportation operations. The methodology followed for sea study analysis is done by determining: